The spindle is one the most essential components in advanced manufacturing where precision and reliability are not at risk. It’s whether it’s sculpting aerospace-grade alloys or fine-tuning high tolerance components for medical devices the machining spindle can be the unseen force behind precision, speed, and the utmost consistency.

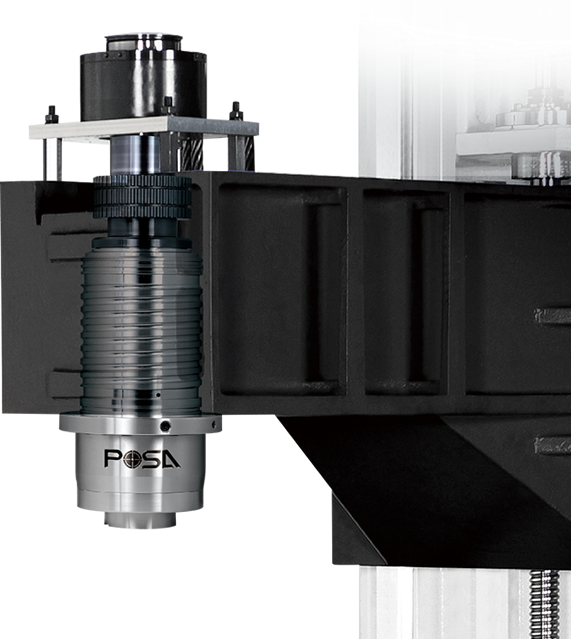

Elite spindle makers like POSA are leading this niche sector, redefining the quality and endurance of machines used in industrial environments.

Image credit: posa-spindle.com

The Spindle is the heart of the Machine

The spindle is at the center of all CNC machines. The spindle powers the tool with high precision, stability, and torque. Spindles that have been misaligned or not properly constructed could result in malfunctioning parts, damage to machines and cut down on the tool’s life. They also may disrupt the process of production.

This is where precision spindle technology makes all the difference. Precision spindles are different from standard parts, are developed, examined and calibrated carefully to meet the demands of extreme and high-demand conditions.

POSA Machinery: More than just a Spindle Maker

POSA Machine has been a leader in spindle manufacturing for decades. While many spindle producers claim to have high precision however, they lack the expertise and engineering expertise that POSA has gained over those years. Spindles made by POSA are famous for their strict in-house quality standards and rigorous testing methods. They also develop solutions that are based on performance to meet the diverse demands of modern-day industry.

From high-speed micro-machining tools to a heavy-duty material removal system POSA’s spindles can be found in everything from grinding machines for tools to horizontal and vertical machining centers. Every spindle goes through a rigorous R&D process that focuses not just on the performance of the spindle, but also on its longevity and thermal stability.

The Evolution of the CNC Lathe Spindle

The CNC lathe spindle has seen remarkable innovation in recent years. Today’s spindles are more than just a rotating shaft. They incorporate sensors and cooling systems along with a smart balancing mechanism. POSA CNC spindles offer an excellent example. They blend superior torque and speed together with a high degree of rigidity and precision, making it possible for machinists to operate with delicate materials and metals. Incorporating advanced ceramic bearings and quality steel, these spindles minimize thermal expansion while maintaining the tight tolerances during long runs. This kind of dependability translates directly into better quality parts and decreased downtime.

Specialized Machining Spindles that meet real-world Needs

It’s impossible to find a machining spindle that fits all, especially in industries such as aerospace, automotive, and die manufacturing. POSA recognizes that each application needs specific requirements. Whatever the spindle’s speed or load capacity or even environmental protection, POSA can meet them. They offer customized spindle configurations in accordance with the particular requirements of each customer. POSA can offer the technical support and flexibility that modern companies demand, whether it is designing a vertical milling spindle or integrating a higher-frequency spindle within a compact unit.

More Than Machines: A Promise to Craftsmanship

The POSA philosophy is what differentiates it from other spindles. The company’s ethos is a blend of skill and innovation. Their design engineers work with clients to learn about their requirements, listen to them and constantly enhance the products they provide. When uptime and consistency are the most important factors to the efficiency of a manufacturing line, choosing the right spindle partners is crucial.

Final Thoughts

The future of manufacturing doesn’t just depend on higher-speed machines. It is dependent on smarter, more robust components. POSA Machine is a fantastic example of what spindle makers can accomplish by combining technological know-how with a mindset of customer-first. The best spindle will transform your idea. This is true whether it’s high-performance CNC lathe spindle that is built to last for a long time, a heavy duty spindle made to handle machining or an extremely precise precision spindle.